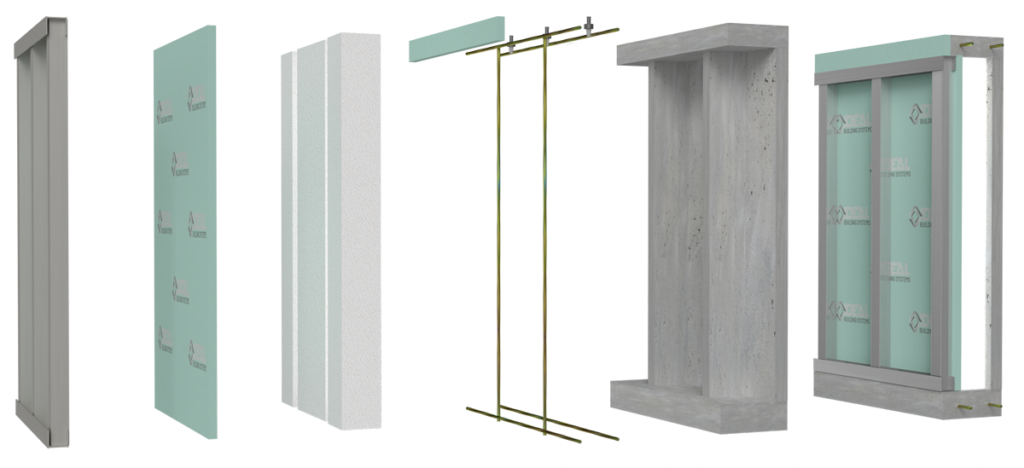

The main components of an Ideal Wall consist of 5000 psi fiber reinforced concrete, rebar, rigid foam insulation and commercial grade steel studs. These components are carefully placed in “book-matched” steel forms, to ensure a perfect fit when installed on your site. Then, we monolithically pour our on-site mixed, fiber reinforced 5000 psi concrete, which bonds these components together to create our high performance Ideal Walls.

The costs are comparable. However…

Here’s Where You Gain Value!!!

Installation for most jobs takes one day or less! Coupled with a well planned and executed project schedule, our rapid installation can save you weeks of time and have your new building “in the dry” quickly so other trades can proceed with their scope of work sooner.

Concrete is far more fire resistant than wood and our walls are designed, tested and have passed the UL 1715 Fire Test. This means you can rest assured that Ideal Walls will provide an added level of safety and security should a fire ever occur.

The engineered design of standard Ideal walls can support 4,000 pounds per linear foot and can be modified to support point loads of 32,000 pounds. This capacity is more than sufficient to meet the structural design specifications for homes and commercial buildings up to 3 stories in height.

Ideal Walls were initially designed to withstand the harsh environment of below grade applications, such as crawlspaces and basements, and therefore provide excellent protection in above grade applications.

The 5000 psi concrete used is extremely durable, inherently damp-proof and air-sealed. Ideal walls reduce, or eliminate, damage caused by natural disasters, pests, mold/mildew, and rot providing a safer and lower maintenance structure. Additionally, the thermal mass of concrete helps reduce temperature fluctuations inside. All this adds up to provide you with a drier, safer, healthier, and more comfortable indoor environment for the life of your home or commercial building.

Ideal Walls are produced following a strictly designed process in a controlled environment at our manufacturing facility. This allows us to use less resources/materials and produce less waste all while producing a stronger, more precise and higher performing wall system. The installation process also reduces impacts to the job site and further reduces waste. The durability and longer useful life of ideal Walls requires less maintenance and repairs over the life of the structure, further reducing the use of resources/materials. The energy efficiency further reduces cost and environmental impacts. This means that you can help protect the environment by choosing to use Ideal Walls instead of traditional concrete, masonry or wood building materials. Let’s build better!

Ideal Walls come with a 15 year warranty against structural defects and side wall water penetration so you can be confident that Ideal Walls will out perform traditional wall assemblies.

About Us

Ideal Building Systems

offers the premier sustainable

insulated concrete wall systems

for the building industry.

Main Location

7112 Mount Hermon Church Road

Durham, NC 27705

Copyright © 2023 Ideal Building Systems. All Rights Reserved